TRUMBULL ANODE CAPS are designed for fighting corrosion of underground bolts and nuts, and iron pipe and fittings. These threaded hex head caps, when secured to a bolt or stud, become the sacrificial anode, corroding, while the remaining metal parts are protected. This corrosion protection continues until the Zinc is consumed.

How Zinc Caps Work

Corrosion is an electrochemical process in which dissimilar metal parts form a galvanic cell when they are in contact with moisture. Using the common battery as an example, moisture becomes the electrolyte while the different metals in the system (such as bolts, nuts, fittings etc.) become the positive and negative ends of the battery. The “more negative” component loses material through corrosion while protecting the “positive” component, which becomes shielded. Zinc being much more negative than most other materials, the protected component is essentially immune to corrosion as long as there is Zinc remaining to consume. Zinc Anode Caps offer protection for other system components made of steel, cast iron, ductile iron, brass and copper shown here. The quantity of Zinc Anode Caps used determines the service life of the protected component.

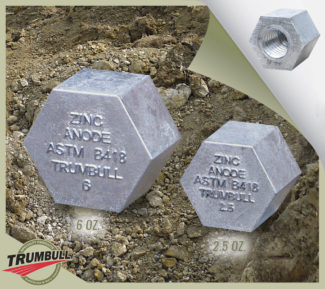

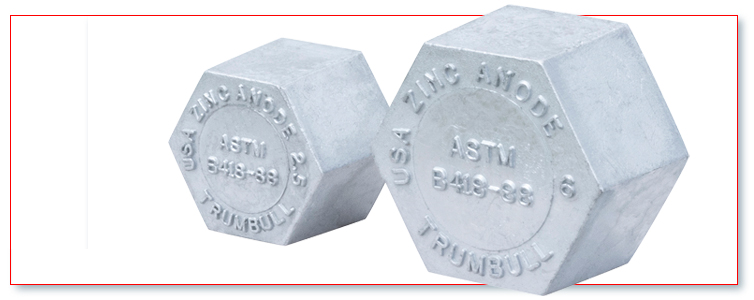

2.5 OZ. SMALL ZINC ANODE CAPS

| Size | Trumbull Item No. |

|---|---|

| 5/8"-11, N.C. | 364-1004 |

| 3/4"-10, N.C. | 364-1006 |

6 OZ. LARGE ZINC ANODE CAPS

| Size | Trumbull Item No. |

|---|---|

| 5/8"-11, N.C. | 364-1008 |

| 3/4"-10, N.C. | 364-1010 |

| 7/8"-9, N.C. | spec/order |

| 1"-8, N.C. | 364-1012 |

Please inquire about Anode Caps with different weights or shapes.